Outsourcing the manufacturing of your products is a very important decision for your company that can have a major impact on your bottom line. Outsourcing can undoubtedly have key benefits for your company. The most tangible benefit is the cost savings in terms of labor costs and capex. It also eliminates all the headaches of dealing with manufacturing processes and labor issues, so you can focus on research and development and marketing your products.

Outsourcing the manufacturing of your products is a very important decision for your company that can have a major impact on your bottom line. Outsourcing can undoubtedly have key benefits for your company. The most tangible benefit is the cost savings in terms of labor costs and capex. It also eliminates all the headaches of dealing with manufacturing processes and labor issues, so you can focus on research and development and marketing your products.

However, outsourcing can also be fraught with challenges. Ensuring quality control of your products as well as the security of your proprietary technology and intellectual property are very important considerations in choosing a manufacturing partner. Many countries offer various advantages for manufacturing your products. It’s important to consider the economic and legal environment in the country you plan to outsource and also consider the pedigree and experience of the company you will be entrusting the manufacturing of your product.

“Best Country to Invest In”

The Philippine electronics industry is now the top performing industry in the Philippines. In 2018, the Philippines exported US$37.57 billion worth of electronic products, which accounted for 57.2% of the country’s total merchandise exports.

The Semiconductor and Electronics Industries in the Philippines Foundations, Inc. (SEIPI) is projecting a 3% growth in its electronic shipment in 2019 to US$48.841. In contrast, the global industry growth is projected at only 2%, primarily caused by weak exports due to decreased global demand as a result of trade tensions between the United States and China.

China’s trade war with U.S. are forcing many electronics manufacturers to look for alternative production bases in Asia to relocate or diversify their production. Unlike Vietnam, Indonesia or Myanmar, the alternative production bases in Southeast Asia that can boast cheap labor, the Philippines’ comparative advantages and opportunities lie in its English-speaking skilled labor, and management capabilities, notes Hong Kong Trade Development Council. The Philippines also lies in the mid-range among ASEAN countries in terms of manufacturing gross value added, surpassing Malaysia and way ahead of Vietnam.

For Multi-National Corporations (MNCs) operating in the Philippines, the country’s robust economy has made it remarkably resilient to external shocks. In addition, the country’s enduringly strong macroeconomic fundamentals make the Philippines the best investment destination in Southeast Asia.

The Philippines registered strong economic growth of 6.8% in 2016, 6.7% in 2017 and 6.2% in 2018, ranking it among the fastest-growing economies in the world. This momentum is expected to continue, with projected annual growth of more than 6.3% over the next five years.

The U.S. News and World Report holds a similarly high opinion of the profitability and viability of the Philippines as the top investment destination. It named the Philippines the “Best Country to Invest In” in 2018. “In contrast to declining inflows of foreign direct investment, or FDI, to Southeast Asia as a whole, the Philippines continued to perform well, according to United Nations data,” wrote the respected media and research firm in its global 2018 Best Countries report.

As a result, The Philippines has become a magnet for foreign direct investments in Asia on account of its liberalized and business-friendly economy. It allows 100% foreign ownership in almost all sectors and has been enhancing its global exposure via trade and inward investment promotion.

Special Export Processing Zones

To stimulate foreign investment and promote its manufacturing and export sectors, the Philippines has formed Special Export Processing Zones (SEPZ) which are essentially enclaves outside of the country’s “normal customs territory.” SEPZs concentrate firms focusing on the export market in special zones. These zones have a high standard of on-site and off-site infrastructure, and companies locating in the zones are granted fiscal incentives. Goods, materials and capital inputs are allowed in the zone to come in and out free of duty and exchange controls. There are over 300 SEPZs operating in the Philippines today.

Automated Technology Philippines, Inc. – Your Strategic Manufacturing Partner

One contract manufacturing company that has thrived in one of the Philippines‘ SEPZ is Automated Technology Philippines, Inc. (ATEC) located at the Light Industry and Science Park in Cabuyao, Laguna - about 30 minute drive from the Philippine capital of Manila’s International Airport.

Starting out as a provider of semiconductor assembly and test services in 1996, ATEC has evolved as a strategic contract manufacturing company for many of the world’s leading technology companies. It now has developed a unique expertise in multi-chip manufacturing techniques and has diversified its capabilities in voice and data communications, including satellite communications, as well as in automotive application packages and optoelectronics. ATEC has over 1,600 employees in two plants with another plant being planned for operation in 2020.

Starting out as a provider of semiconductor assembly and test services in 1996, ATEC has evolved as a strategic contract manufacturing company for many of the world’s leading technology companies. It now has developed a unique expertise in multi-chip manufacturing techniques and has diversified its capabilities in voice and data communications, including satellite communications, as well as in automotive application packages and optoelectronics. ATEC has over 1,600 employees in two plants with another plant being planned for operation in 2020.

ATEC Phils. Inc Capabilities

ATEC Phils., Inc. has two main divisions: Semiconductor and Connectivity. ATEC Semiconductor provides a full array of semiconductor assembly and test services, ranging from discrete to complex multichip packages, from low volume, quick turns to high volume production.

The second division, ATEC Connectivity, has over 20 years proven track record and experience in manufacturing high technology Radio Frequency (RF), microwave and millimeterwave products for existing and emerging Original Equipment Manufacturers (OEMs) and Original Design Manufacturers (ODMs). Backed by ATEC’s extensive experience in outsourcing electronics manufacturing services, with its pioneering “captive line” concept and its world-class production facility, ATEC Connectivity is providing cost-effective, high-quality manufacturing solutions for complex products with frequencies ranging from DC to 90 GHz.

A vertically integrated manufacturing company, ATEC produces from components, modules, sub-systems, and up to system level products including RF Test and Tune, complex PCBA, hybrid assembly and ATE developments.

ATEC Connectivity provides SMT/PCB assembly, MIC/thin-film assembly, complex box build assembly, RF, microwave and millimeterwave, testing (modules, sub-systems and systems) and supply chain management. Its plant has a total land area of 56,000 sq.m. (604,000 sq.ft.) with total production and office area of 30,000 sq.m. (323,000 sq.ft.). ATEC Connectivity has the resources to expand upon the demand of its customers.

ATEC Connectivity provides SMT/PCB assembly, MIC/thin-film assembly, complex box build assembly, RF, microwave and millimeterwave, testing (modules, sub-systems and systems) and supply chain management. Its plant has a total land area of 56,000 sq.m. (604,000 sq.ft.) with total production and office area of 30,000 sq.m. (323,000 sq.ft.). ATEC Connectivity has the resources to expand upon the demand of its customers.

Security

As mentioned earlier, a key consideration when outsourcing abroad is the security of your intellectual property (IP). The Philippines adheres to the Paris Convention for the Protection of Industrial Property Rights, the Patent Cooperation Treaty, the TRIPS Agreement, among others. In this light, intellectual property such as copyright, trademark, patent, utility model, industrial design are protected in the Philippines. The governing law is Republic Act No. 8942, otherwise known as the Intellectual Property Code of the Philippines.

ATEC is very mindful of protecting its customer’s IP. The first thing they do even with potential customers is sign Non-Disclosure Agreements (NDA). All documents provided its employees do not mention the client’s name.

Quality Control

ATEC Phils. Inc. has earned ISO 9001:2015 / IATF 16949:2016 and ISO 14001:2015 quality certifications. It uses the IPC 610-A and MIL-STD-883 electronics manufacturing standards and has quality assurance and control procedures in every stage of the manufacturing process. “One thing we emphasize is the quality of our products. The products we manufacture in our facility actually are fully tested. They are exposed to all kinds of extreme weather conditions. We have a very stringent quality control system that ensure that the products we manufacture for our customers are of the highest quality,” said Domingo Bonifacio, Executive Vice-President and General Manager of ATEC Connectivity.

One Stop Shop

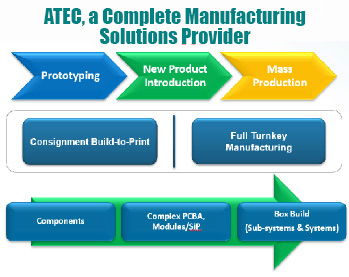

ATEC Connectivity is a complete electronic manufacturing solutions provider specialized to RF, microwave and millimeterwave electronic manufacturing services. It provides services from consignment to full turnkey business and can work in different stages of the product life cycle from prototype to NPI to mass production. Its capabilities includes complex PCBA, hybrid and chip-on-board, module/System in Package (SiP), test/evaluation boards and box-build assembly. It assembles and tests high frequency microwave/millimeter wave devices, integrated circuits, discrete components, IoT devices, and Printed Circuit Board assemblies. It has system level integration and testing capability of telecommunications, satellite communications, aerospace and various wireless products.

ATEC Connectivity is a complete electronic manufacturing solutions provider specialized to RF, microwave and millimeterwave electronic manufacturing services. It provides services from consignment to full turnkey business and can work in different stages of the product life cycle from prototype to NPI to mass production. Its capabilities includes complex PCBA, hybrid and chip-on-board, module/System in Package (SiP), test/evaluation boards and box-build assembly. It assembles and tests high frequency microwave/millimeter wave devices, integrated circuits, discrete components, IoT devices, and Printed Circuit Board assemblies. It has system level integration and testing capability of telecommunications, satellite communications, aerospace and various wireless products.

“We are actually a one-stop-shop. We are an integrated manufacturing facility. We cover consignment to full turnkey business and we can engage with customers in all phases of the product life cycle from design verification, prototyping, new product introduction, pre-production to mass production and up to direct drop shipment to end customers and repair management. All you need to do is give us the specifications and design of the product and we will take care of everything including shipping your products directly to your end-customers,” said Bonifacio. ”We are not just your manufacturer, but your strategic partner,” he added.

Outsourcing might be one of the most important business decisions a company can make. There are many options, but in the final analysis, you are better off with choosing not just a contract manufacturer but a strategic partner for your business.

Click here to view a video tour of ATEC Phils. Inc., Manila, Philippines.

-----------------------------------------

Peter I. Galace is the Associate Editor of Satellite Markets and Research. He writes extensively on telecommunications and satellite developments in Asia and other regions for numerous publications and research firms. He can be reached at: peter@satellitemarkets.com.

Peter I. Galace is the Associate Editor of Satellite Markets and Research. He writes extensively on telecommunications and satellite developments in Asia and other regions for numerous publications and research firms. He can be reached at: peter@satellitemarkets.com.